Lin Tang, Junliang Zhang and Junwei Gu*. Random copolymer membrane coated PBO fibers with significantly improved interfacial adhesion for PBO fibers/cyanate ester composites. Chinese Journal of Aeronautics, 2021, 34(2): 659-668. 2019IF=2.215.(2區工程技術期刊,中國科技期刊卓越行動計劃-領軍期刊類項目)

(https://doi.org/10.1016/j.cja.2020.03.007)

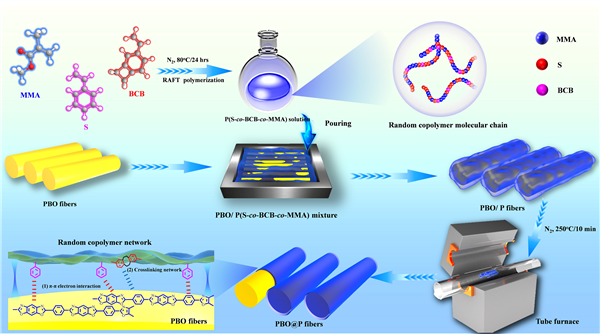

AbstractPoly(p-phenylene-2,6-benzobisoxazole) (PBO) fibers possess excellent dielectric, mechanical properties and heat resistance. However, the surface of PBO fibers is smooth and highly chemical inert, resulting in poor interfacial compatibility to polymer matrix, which severely limits its wider application in high-performance fiber-reinforced resin matrix composites. In this work, random copolymers (P(S-co-BCB-co-MMA)) containing benzocyclobutene in the side-chain were synthesized by reversible addition-fragmentation chain transfer (RAFT) polymerization, which were then utilized to form dense random copolymer membrane on the surface of PBO fibers by thermally cross-linking at 250oC (PBO@P fibers). Four kinds of synthesized P(S-co-BCB-co-MMA) with different number-average molar mass (Mn) were well controlled and possessed narrow dispersity. When the Mn was 32300, the surface roughness of PBO@P fibers was increased from 11 nm (PBO fibers) to 39 nm. In addition, PBO@P fibers presented the optimal interfacial compatibility with bisphenol A cyanate (BADCy) resins. And the single fiber pull-out strength of PBO@P fibers/BADCy micro-composites was 4.5 MPa, increasing by 45.2% in comparison with that of PBO fibers/BADCy micro-composites (3.1 MPa). Meantime, PBO@P fibers still retained excellent tensile strength (about 5.1 GPa). Overall, this work illustrates a simple and efficient surface functionalization method, which would provide a strong theoretical basis and technical support for controlling the surface structure & chemistry of inert substrates.

聚對苯撐苯并二噁唑(PBO)纖維具有優異的介電性能、力學性能和耐熱性能,然而其表面光滑且呈極強的化學惰性,與樹脂基體相容性極差,嚴重限制了其在高性能纖維增強樹脂基復合材料領域更廣的應用。本文采用可逆加成-斷裂鏈轉移(RAFT)聚合合成一種側鏈含有苯并環丁烯的無規共聚物P(S-co-BCB-co-MMA),經熱交聯在PBO纖維表面形成一層致密的無規共聚物膜(PBO@P纖維)。結果表明,經RAFT聚合得到可控的無規共聚物P(S-co-BCB-co-MMA)具有窄的多分散系數,且通過熱交聯(250oC)在PBO纖維表面形成一層無規共聚物膜。當P(S-co-BCB-co-MMA)的分子量(Mn)為32300時,PBO@P纖維的表面粗糙度從11 nm(PBO纖維)提高到39 nm,與雙酚A型氰酸酯(BADCy)樹脂的界面相容性最佳。且PBO@P纖維/BADCy樹脂微復合材料的單絲拔出強度為4.5 MPa,較PBO纖維/BADCy樹脂微復合材料的單絲拔出強度(3.1 MPa)提高了45.2%。同時,PBO@P纖維仍保留PBO纖維優異的拉伸強度(5.1 GPa)。此外,本文采用簡單、高效的表面改性技術為調控惰性基質表面結構和表面化學提供強有力的理論依據和技術支撐。