Fengqi Qi#,

Lei Wang#, Yali Zhang, Zhonglei Ma*, Hua Qiu and Junwei Gu*.

Robust Ti3C2Tx MXene/starch derived carbon

foam composites for superior EMI shielding and thermal insulation. Materials

Today Physics, 2021, 21: 100512. 2020IF=9.298.(1區材料科學Top期刊)

https://doi.org/10.1016/j.mtphys.2021.100512

Lightweight and robust

electromagnetic interference (EMI) shielding materials are highly desirable in

high-end precision electronic components and 5G communication system. Herein,

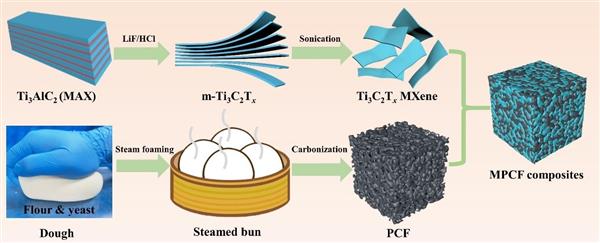

the starch based porous carbon foam (PCF) is prepared by yeast fermentation, steam foaming and carbonization approach with flour as raw

material. And the Ti3C2Tx MXene/PCF (MPCF)

composites are then fabricated via vacuum assisted impregnation of Ti3C2Tx MXene

followed by freeze drying. The obtained PCF carbonized at 1400°C presents

excellent compression strength of 4.9 MPa and superior electrical conductivity

(σ) of 21.8 S/cm, respectively. The corresponding MPCF composites with

8.5 wt% Ti3C2Tx MXene exhibit superior EMI

shielding effectiveness (EMI SE) and specific shielding effectiveness (SSE, EMI

SE/ρ) of 75 dB and 216.9 dB·cm3/g, respectively. Meanwhile,

the MPCF composites possess excellent flame retardancy and outstanding heat

insulation, and can be applied in the extreme environment. The resultant

lightweight, robust and multifunctional MPCF composites with simple fabrication

processes show broad application prospects for EMI

shielding system in

aerospace, military engineering, electrical and electronics fields.

在高端精密電子元器件和5G通信系統中,輕量化、高強度電磁干擾(EMI)屏蔽材料尤為重要。本研究以面粉為原材料,通過酵母發酵、蒸汽發泡和碳化工藝制得淀粉基多孔碳泡沫(PCF),并通過真空輔助浸漬和冷凍干燥引入Ti3C2Tx MXene制得MXene/多孔碳泡沫(MPCF)復合材料。PCF復合材料兼具輕質高強和高導電特點,1400°C下碳化得到的PCF的ρ、壓縮強度和電導率(σ)分別為0.32 g/cm3、4.9 MPa和21.8 S/cm。當Ti3C2Tx MXene用量為8.5

wt%時,MPCF復合材料的電磁屏蔽效能(EMI SE)和比屏蔽效能(SSE,EMI SE/密度(σ))分別達到75 dB和216.9 dB·cm3/g;同時兼具出色的阻燃性能和良好的隔熱性能,可適用高溫灼燒的極端環境。這種制備簡單的多功能超輕碳材料在航空航天、軍事工程和電子電器等領域的EMI屏蔽系統中展現出廣闊的應用前景。