從海水和廢水中高效提取淡水和清潔水,可有效解決全球水短缺問題,具有廣泛的前景。傳統的淡水提取策略通常采用膜技術或熱技術,過濾和反滲透等膜技術被廣泛用于家庭獲取清潔水,基于熱能的水提取方法通常用于工業加熱蒸餾,但這兩種技術都不可避免地需要大量化石能源來維持高壓或高溫,從而導致高能耗和環境污染。因此,開發高效、低成本、可持續的海水淡化和廢水處理技術日益迫切。

在各種淡水提取技術中,太陽能蒸汽發生器(Solar Steam Generator,SSG)尤其具有吸引力,因為它利用太陽能加熱水并產生蒸汽,然后將蒸汽凝結成清潔水。近年來,太陽能蒸汽發生器因其成本低廉和環境效益而備受關注,然而,SSG 的太陽能轉換效率相對較低,嚴重限制了其更廣泛的應用。在傳統的 SSG 系統中,太陽光加熱整個水體,導致水體溫度低,太陽能轉換效率低。為了提高效率,通常采用加熱管的太陽能集熱器來提高水溫,或者使用閃蒸或多效蒸餾裝置加速冷凝水蒸氣。然而,地球表面的太陽能密度相當低(1個太陽強度約為 1 kW m-2),因此需要大型、昂貴和復雜的太陽能聚光器來維持合理的 SSG 效率。

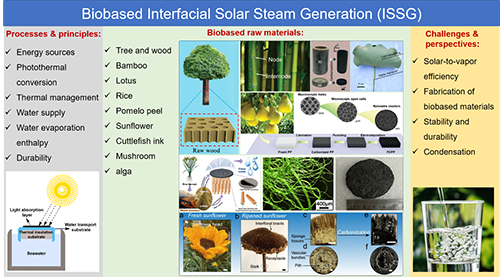

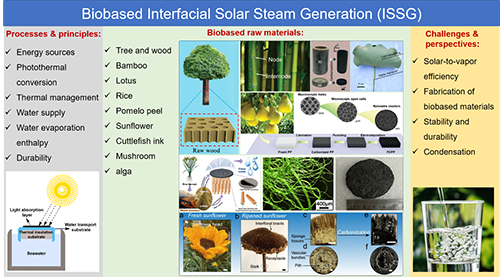

為了以最低的能耗和材料成本滿足人們對淡水的迫切需求,界面太陽能水蒸汽發生器(Interfacial SSG,ISSG)技術應用而生,這是目前最有前途的海水淡化和廢水處理技術之一。典型的 ISSG 系統由兩部分組成:1)位于水氣界面的 ISSG蒸發器;2)集水器。在太陽能驅動的水凈化過程中,ISSG 蒸發器將太陽能轉換成的熱量集中在水-空氣界面上,顯著提高了界面的局部溫度,極大地提高了水蒸氣生成效率。ISSG蒸發器通過毛細管力和不斷的界面水蒸發,將液態水不斷地泵送到水-空氣界面上,并氣化成水蒸氣,然后通過集水器從水蒸氣中冷凝收集新鮮或清潔的水。生物基材料因其豐富性、可再生性、可生物降解性和低成本等優勢,取代化石燃料材料已成為一種趨勢。構建具有高效率和可持續的生物基 ISSG 蒸發器已成為 ISSG 領域最熱門的研究課題之一。華南師范大學周國富教授團隊張振課題組徐佑森等以“Bio-based interfacial solar steam generator”為題在Renewable and Sustainable Energy Reviews(中科院一區JCR一區,IF 16.3)上發表綜述性論文(DOI:10.1016/j.rser.2024.114787)。在這篇綜述中首先介紹了 ISSG 器件的最新發展,重點闡述了設計 ISSG 蒸發器時提高效率和耐用性的關鍵工藝的一般原理;然后介紹了各種生物基 ISSG蒸發器(包括木材、竹子、荷花、稻草、柚子皮、向日葵、墨魚汁、蘑菇和藻類),通過揭示這些生物基材料的結構和成分,分析它們可以增強光吸收或水傳輸能力的內在原理;此外,本篇綜述還討論了如何利用具有集水能力的生物來設計生物基或仿生集水器;最后,還討論了設計新型生物基 ISSG 系統有關的挑戰和前景。本綜述旨在啟發創新思路,制造高效、可持續的生物基 ISSG 蒸發器,從海水和廢水中提取新鮮潔凈的水。

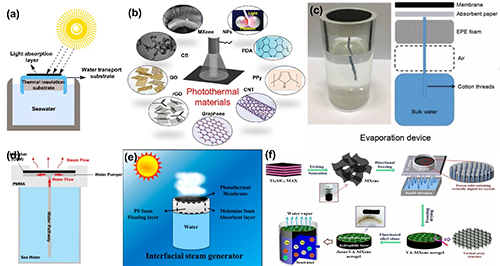

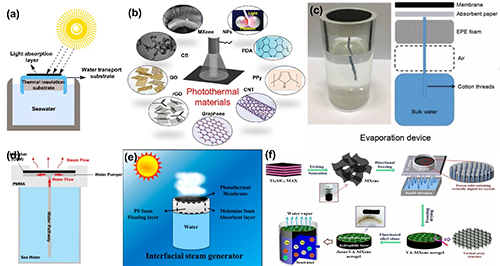

本文首先介紹了了設計 ISSG 蒸發器時提高效率和耐用性的關鍵工藝的一般原理。典型的 ISSG 蒸發器一般由兩部分組成: (1) 上部的光吸收層用于吸收太陽光并將其轉化為熱能;(2) 下部放置或連接的基底系統用于平衡熱管理和供水。要設計和建造高效、穩定的 ISSG 蒸發器,必須具備以下特性: (1) 在水面上穩定發熱;(2) 強勁的光吸收和光熱轉換;(3) 從環境中收集能量;(4) 低熱導率,以減少熱量損失;(5) 設計良好的輸水通道,通過毛細力將水輸送到水氣界面,確保不間斷供水;(6) 快速釋放水蒸氣;(7) 低蒸發焓;(8) 耐久性和高穩定性。基于此,作者對這些特性進行了分類,從能量來源、光熱轉換效率、熱能利用效率、水供應和低蒸發焓,以及ISSG蒸發器耐久性等6大方面詳細闡述了這些特性如何協同提高 ISSG 蒸發器的效率和穩定性。

Figure 1. (a) A typical ISSG device; (b) commonly used photothermal materials; ISSG devices with cotton threads (c), T-shaped water carriers (d), and MF form (e) as water carries; (f) fabrication process of Janus MXene aerogel.

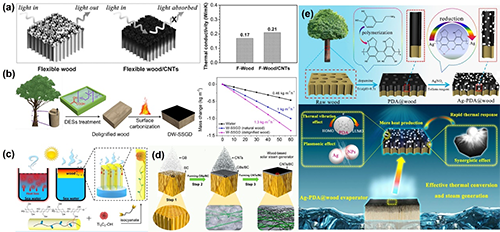

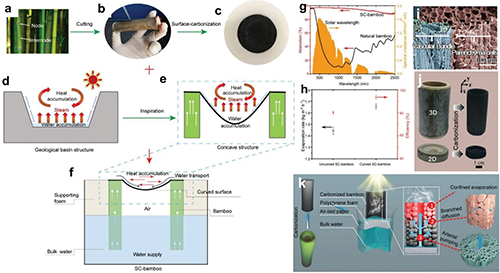

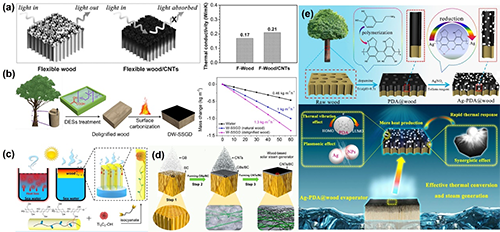

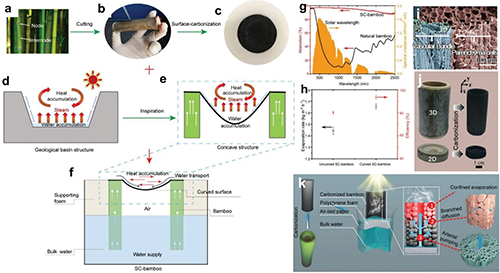

我國是農業大國,許多作物在收割后會產生大量的生物質廢物,造成嚴重的環境污染,需要投入大量人力物力進行處理。因此,利用資源豐富、可再生、可生物降解和成本低廉的生物資源取代化石燃料材料,也就是構建生物基 ISSG 蒸發器,可以有效降低環境污染的同時,也能控制ISSG蒸發器的構造成本,進一步降低水的單價。而了解生物的特性及其機制原理,是利用和模仿的前提。在第三章中,作者介紹了各種生物,包括樹木、竹子、荷花、向日葵、柚子皮和稻草等有關ISSG的組織結構及其作用機理,并重點概述了基于生物基材料的 ISSG 蒸發器的最新發展。特別地,利用柚子皮和收割后的稻草等農業廢棄物制備ISSG蒸發器,不僅可以廢物利用,還可以降低人工處理成本與防止環境污染。

Figure 2. (a) Flexible wood/CNTs as ISSG and the thermal conductivity of flexible wood and flexible wood/CNTs; (b) fabrication of delignified wood by deep eutectic solvent treatment, surface carbonization of DW and its ISSG performance; (c) fabrication of Ti3C2-wood by isocyanate; (d) fabrication of hierarchical solar steam generator with glass hollow balls, BC and CNTs; (e) fabrication of Ag-PDA@wood as ISSG.

Figure 3. Photographs of (a) the pristine bamboo, (b) a typical bamboo culm, and (c) the surface-carbonized integrated bamboo; (d) schematic of a geological basin structure; (e) schematic of the unique concave structure at the nodes; (f) surface-carbonized integrated bamboo used in an ISSG device; (g) UV–vis–NIR absorption spectra of surface-carbonized integrated bamboo; (h) Evaporation rate and efficiency of uncurved/curved surface-carbonized integrated bamboo in bulk water under 1 sun illumination; (i) scanning electron microscope (SEM) micrographs showing vascular bundles and parenchyma cells; (j) photograph of natural bamboos before and after carbonization; (k) schematic illustration of the ISSG device with carbonized bamboo.

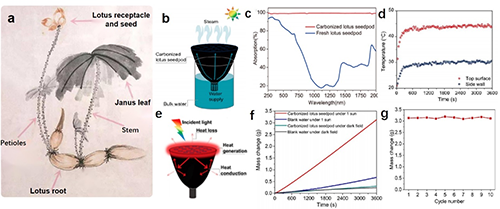

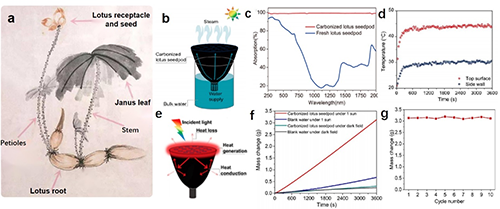

Figure 4. (a) Schematic of the composition of lotus; (b) schematic of the carbonized lotus seedpod as photothermal materials; (c) UV–vis–NIR absorption spectra; (d) temperature changes of the top surface and side wall of the carbonized lotus seedpod over time during the solar steam generation process; (e) schematic of heat management in carbonized lotus seedpods; (f) real-time water mass changes of carbonized lotus seedpod and blank water under dark conditions and 1 sun illumination, respectively; (g) evaporation cycle performance of the carbonized lotus seedpod, with each cycle sustained over 3600 seconds.

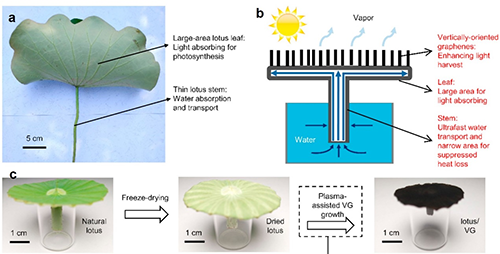

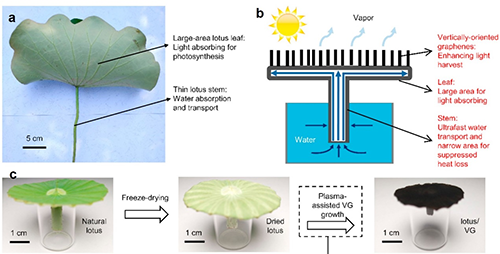

Figure 5. (a) Nature lotus leaf with large area for light absorbing and lotus stem for water transportation; (b) schematic of lotus-based energy and water conversion system; (c) fabrication of lotus/vertically-oriented graphene via freeze-drying and plasma-assisted vertically-oriented graphene growth.

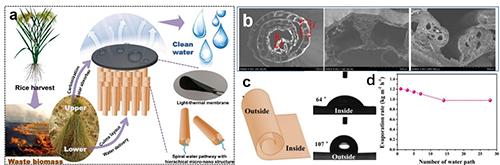

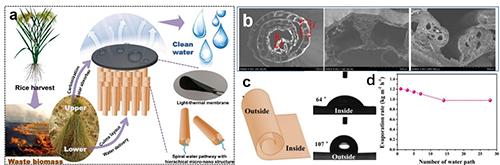

Figure 6. (a) Illustration of the design route of the rice-based ISSG; (b) cross-section of an internode part in the rice straw culm; (c) hydrophilic inside and hydrophobic outside surface of the culm wall; (d) evaporation rate of bio-based photothermal membrane equipped with different number of rice straw pipes as the water path under 1 kW m?2 solar illumination.

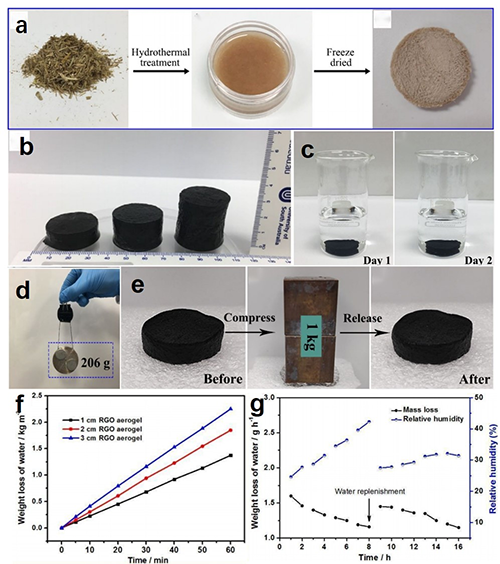

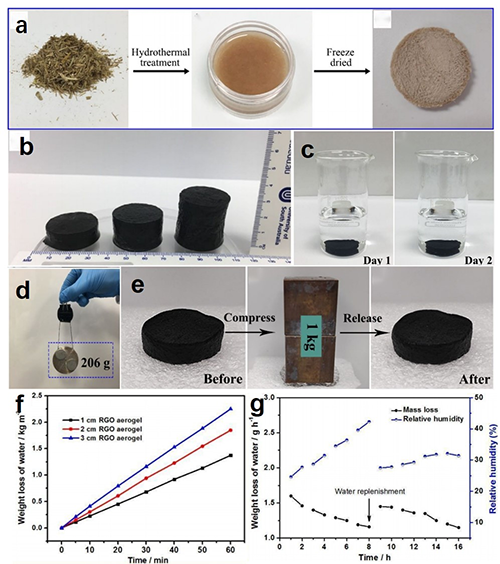

Figure 7. (a) The fabrication process of cellulose aerogel; (b) final cellulose aerogels with different heights; (c) cellulose aerogel after being immersed in water and sonicated for 5 minutes and after emersion in water for 24 hours; (d) wet cellulose aerogel against a pulling weight of 206 g; (e) cellulose aerogel before, during and after compression. Time-dependent weight loss of water of photothermal aerogels (f) with different height and (g) worked as an isolated device under 1.0 sun irradiation.

Figure 8. (a) The synthesis route of fractal carbonized pomelo peels; (b) the contact angle of carbonized pomelo peels before and after acid treatment; (c) SEM images of the punching hole (I), non-punching region (II), side wall (III), and bottom (IV) of the hole; (d) SEM images showing the thickness of nanowire clusters; (e) scheme of ISSG system; (f) the concentration of four primary ions in simulated seawater sample before and after solar desalination; (g) running cost of different typical desalination technologies and desalination using fractal carbonized pomelo peels; (h) UV–vis spectrum of methyl orange and methyl blue and condensate water.

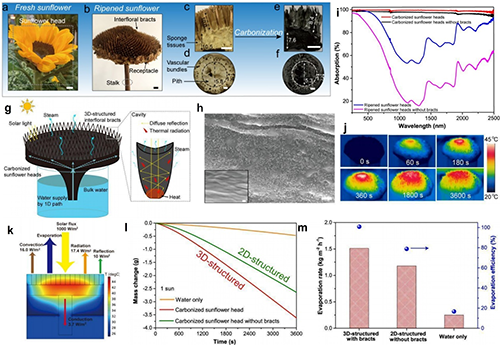

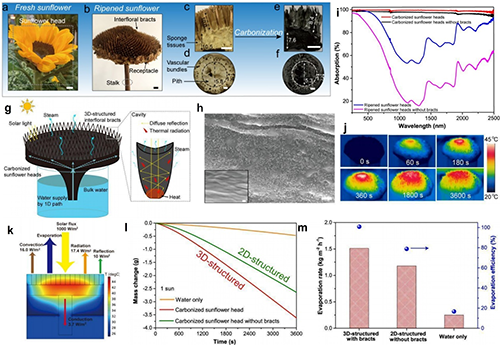

Figure 9. Digital images of a fresh (a) and ripened (b) sunflower head. Cross-section of a ripened sunflower receptacle (c) with thick sponge tissues and stalk (d) with vascular bundles and pith. Digital images of the cross-section of a carbonized sunflower receptacle (e) and stalk (f); (g) schematic of a carbonized sunflower head-based device and a cavity; (h) SEM images of the surface of carbonized interfloral bracts and ripened interfloral bracts in the inset; (i) UV-vis absorption spectra of ripened and carbonized sunflower heads with and without 3D interfloral bracts; (j) IR image of the wet carbonized receptacle was taken under 1 sun; (k) the simulated temperature distribution and heat loss of 3D-structured carbonized sunflower head. Water mass changes (l), evaporation rate and efficiency (m) of the 3D-structured, 2D-structured carbonized sunflower head and water only under 1 sun.

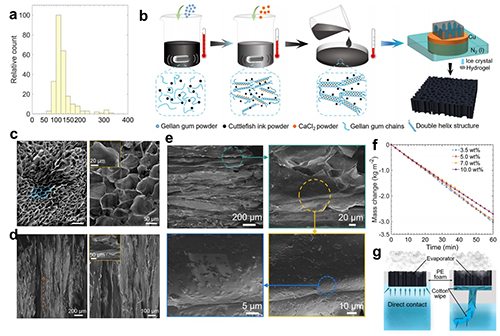

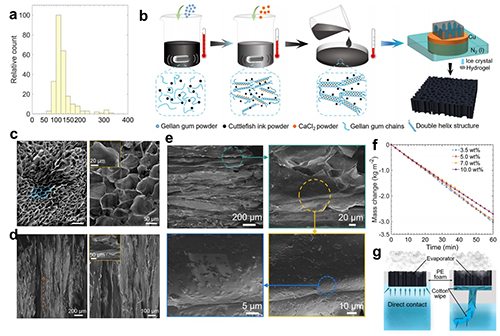

Figure 10. (a) The statistical analyses of the diameters of cuttlefish ink powders; (b) schematic illustration of the fabrication process of the aligned gellan gum/cuttlefish ink hydrogel; (c) SEM images of the longitudinal section of the gellan gum/cuttlefish ink porous structure with vertically aligned microchannels in different magnifications; (d) SEM images of the transverse section of the gellan gum/cuttlefish ink aligned porous structure with numerous open channels in different magnifications; (e) SEM images showing the distribution of cuttlefish ink powder in the longitudinal section of gellan gum/cuttlefish ink aligned porous structure with different magnifications; (f) mass changes of solutions with various salinities for the gellan gum/cuttlefish ink hydrogel evaporator; (g) schematic showing the water supply methods of direct contact with water (left) and a cotton wipe as a water path (right).

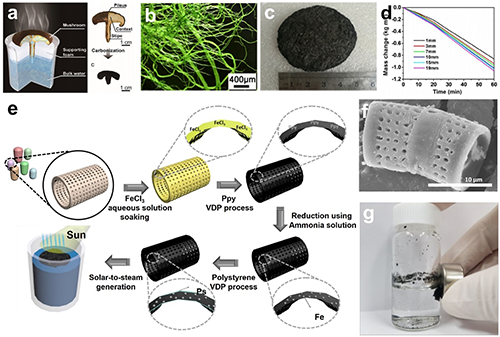

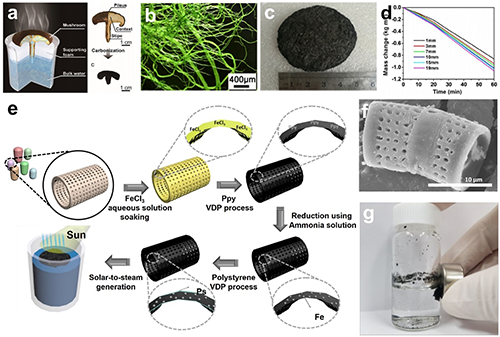

Figure 11. (a) Schematic of mushroom-based ISSG; (b) photograph of original Enteromorpha prolifera fibers; (c) circular carbonaceous Enteromorpha prolifera foam; (d) mass changes of water for the carbonaceous Enteromorpha prolifera foam of different thicknesses under 1-sun illumination; (e) fabrication process of particle-based ISSG device; (f) SEM image of a pristine diatom; (g) response of the of PPyPS-diatoms to an external magnet.

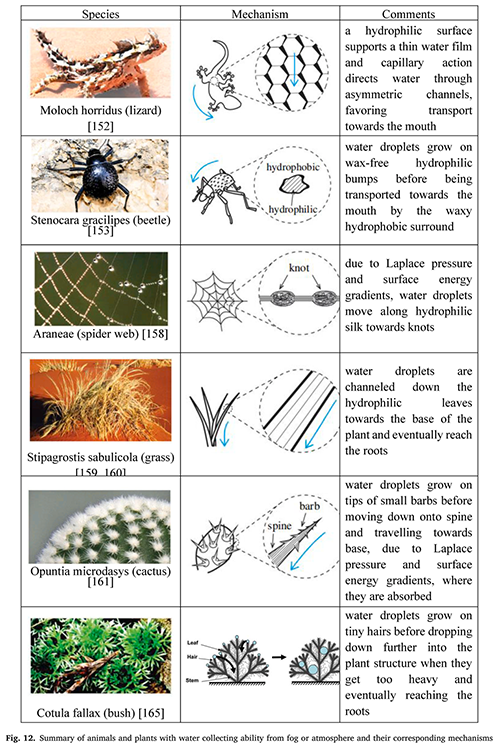

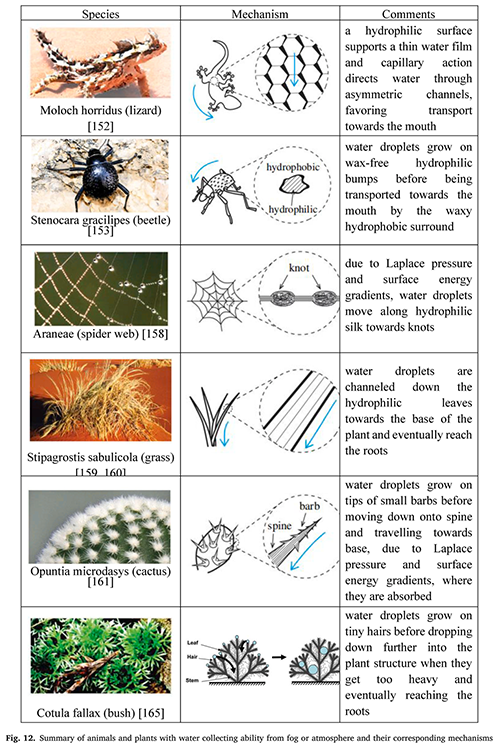

目前,有關 ISSG 的研究大多集中在蒸汽產生方面,特別是光熱層和供水系統。然而,ISSG 的最終目標是收集水蒸氣以生產淡水,因此集水器的質量對最終的太陽能轉化為水的效率有很大影響。以目前的技術而言,在室外實驗中,使用金字塔形或長方體形玻璃蓋板的傳統水汽冷凝集水器,只能達到 30-40% 的集水率,導致 ISSG 的太陽能轉化為水的能量效率低于 36%(假設太陽能轉化為水蒸氣的能量效率為 90%)。集水器的質量已成為 ISSG 的主要瓶頸,但是生物基ISSG集水器的研究仍然很少。因此,作者介紹了幾種自然生物,它們具有獨特的特性,能夠從霧或大氣中收集水,如沙漠中的仙人掌可以從干燥的空氣中獲取水分,這些生物的特性能夠啟發我們為 ISSG 設計高效的集水器和新的冷凝水收集方法。

最后,作者總結了生物基ISSG所面臨的一些挑戰。雖然生物基 ISSG 蒸發器因其低成本、可再生、環保、高效、大規模和易改性等特點在太陽能驅動的水凈化方面具有巨大潛力,但它也面臨著一些關鍵挑戰。作者在第五章中詳細闡述了這些挑戰,也列舉了一系列解決方法與前景,包括:(1)如何提高生物基ISSG蒸發器的太陽能蒸汽轉換效率,現行的利用生物基的方法往往是簡單的碳化,但是這樣很可能會破壞植物本身的結構不利于水運輸,并且許多植物本身的熱導率還是相對較高的,合理的選擇和構建復合光熱材料以及通過改變植物的形態或改變其結構可以有效提高太陽能轉化為水蒸氣的效率;(2)合理有效地從植物廢料中提取出有用和高價值材料,如纖維素和硅,提取出的纖維素可以制備成纖維素氣凝膠;(3)如何提高生物基ISSG蒸發器的工作穩定性和生命,鹽以及微生物堆積會造成蒸發器效率的不穩定,影響ISSG蒸發器工作穩定性,在其他ISSG蒸發器的構建中Janus結構以及加入抗菌材料來提高工作穩定性已有許多報道,但生物基ISSG蒸發器仍很少見;(4)如何高效收集水蒸氣獲得淡水資源,使用傳統的金字塔形或長方體形玻璃蓋板的冷凝集水器效率無法得到保障,也因此阻礙了ISSG技術的商業化,設計高效的集水器和新的冷凝水收集方法可以有效推動ISSG技術的應用于發展。

原文鏈接:https://doi.org/10.1016/j.rser.2024.114787