隨著智能紡織和可穿戴電子設備的快速發展,如何實現既柔性又安全的高性能能源存儲成為科研前沿的重要課題。近日,浙江理工大學紡織科學與工程學院(國際絲綢學院)胡毅教授團隊在國際著名期刊《Nano Energy》(影響因子16.8)在線發表了題為《Janus-structured composite nanofiber membranes with heterointerfacial engineering for high-performance all-solid-state lithium metal batteries》的研究論文。該研究提出了一種具有三維異構界面結構的Janus復合納米纖維膜,顯著提升了固態鋰金屬電池的離子傳輸效率和界面穩定性,為柔性智能紡織器件中的儲能問題提供了創新性的解決方案。論文DOI:10.1016/j.nanoen.2025.111136。本文第一作者為浙江理工大學紡織科學與工程學院(國際絲綢學院)博士研究生李德華,通訊作者為浙江理工大學博士生導師胡毅教授。

在柔性電子設備和高安全儲能系統迅速發展的背景下,固態鋰電池因其優異的熱穩定性與本征安全性,正逐漸成為下一代電池技術的核心方向。然而,單一無機固態電解質雖然導電性強,卻脆弱且難以與柔性電子器件的軟質界面相匹配;而純聚合物電解質雖然柔軟易加工,但離子導電性不足,難以滿足高性能需求。復合固態電解質融合無機納米顆粒的高導電性與聚合物的柔韌性,成為實現高效且安全儲能的主流方案。傳統研究多采用二維層狀結構,但其異質界面面積有限,機械耦合效果不足,制約了材料在智能紡織等柔性領域的廣泛應用。

為此,胡毅團隊創新采用電紡技術,構筑了具有三維互穿Janus異質界面的復合納米纖維膜。該結構在柔軟的PVDF-HFP基底上定向固定LLZO納米顆粒,并結合塑化劑優化聚合物結晶度,實現了離子傳輸路徑的多元化和界面能量勢的優化。該設計不僅顯著提升了膜的機械強度(達到4.24 MPa),還實現了7.60×10-4 S·cm-1(50°C)高離子導電率和0.75的鋰離子遷移數。理論計算顯示,Janus膜表面的C-F官能團及路易斯酸堿活性位點有效促進鋰鹽解離,降低鋰離子遷移能壘,形成穩定的Li3N/LiF界面SEI層,保證了鋰金屬的均勻沉積和長壽命循環。該復合電解質在實際柔性軟包電池中展現出優異性能,能夠驅動織物上的冷光發光裝置(ACEL)和肌電傳感器,在180度折疊、針刺、機械剪切及高溫環境下依然穩定工作,完美契合智能紡織對柔性儲能的需求。該研究不僅從材料結構設計層面突破了傳統固態電解質在機械強度和離子傳輸之間的矛盾,更為智能紡織領域的能源集成提供了強有力的技術支撐。

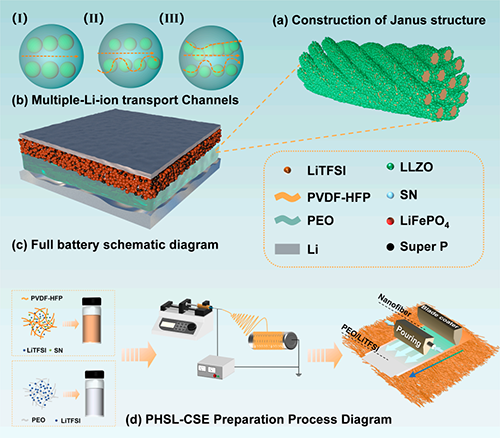

具體而言:該研究引入了一種Janus結構的復合纖維膜,通過在PEO基體內部創建異質界面,提供了多重離子傳輸路徑。這種Janus結構的復合電解質(PHSL-CSE)是通過靜電紡絲技術構建三維互穿網絡實現的。這種Janus結構在PEO-LLZO界面構建了豐富的無機-聚合物異質界面,調控了離子傳輸行為,形成了多種鋰離子傳輸通道:(i) PEO基體內的鏈段運動;(ii) LLZO顆粒形成的連續相;(iii) PEO-LLZO異質界面的空間電荷層。這些機制協同作用,顯著提高了鋰離子在電解質內的傳輸效率。

Fig. 1. Schematic illustration of the ion transport mechanism and fabrication process of the PHSL-CSE composite solid electrolyte with a three-dimensional interconnected Janus structure.(a) Representation of the Janus-structured composite fiber membrane, showcasing its unique heterogeneous interface and architecture.(b) Illustration of the multiple lithium-ion transport pathways enabled by the Janus structure, highlighting the role of the interconnected network in facilitating efficient ion migration. (c)Schematic of the full-cell configuration assembled with the PHSL-CSE composite solid-state electrolyte, demonstrating its integration into a practical solid-state lithium battery. (d) Step-by-step fabrication process of the PHSL-CSE composite electrolyte, emphasizing the formation of the Janus structure and the incorporation of functionalized components.

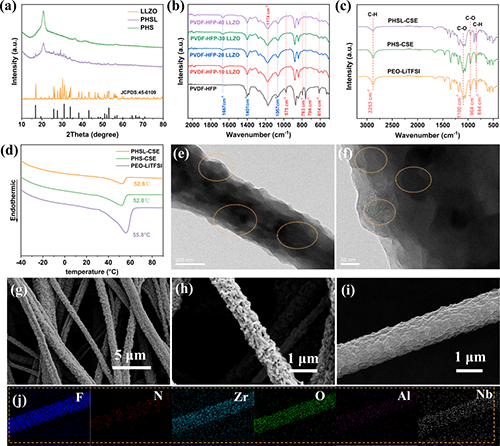

通過X射線衍射(XRD)、透射電子顯微鏡(TEM)、掃描電子顯微鏡(SEM)和元素映射等手段對材料進行了表征。結果證實了Janus結構的成功構建以及LLZO顆粒在纖維表面和內部的均勻分布。這確保了連續的離子通道和良好的界面相容性。傅里葉變換紅外光譜(FTIR)分析表明,LLZO的加入降低了PVDF-HFP的結晶度,LLZO和SN協同促進了PVDF-HFP的脫氟化氫反應。差示掃描量熱法(DSC)顯示,Janus結構納米纖維的引入顯著抑制了PEO鏈段的結晶。熱重分析(TGA)和高溫測試表明,PHSL-CSE電解質具有優異的熱穩定性和尺寸穩定性。機械性能測試顯示,該電解質具有高機械強度(4.24 MPa)和良好的柔韌性。

Fig. 2. Comprehensive characterization of the Janus fiber membrane and electrolytes across different systems. (a) X-ray diffraction (XRD) patterns of LLZO, PHS-CSE, and PHSL (Janus) composite fiber membranes. (b) Attenuated total reflection Fourier-transform infrared (ATR-FTIR) spectra of PHSL fibers with varying LLZO content. (c) ATR-FTIR spectra of PEO-LiTFSI, PHS-CSE, and PHSL-CSE solid electrolyte films. (d) Differential scanning calorimetry (DSC) curves of PEO-LiTFSI, PHS-CSE, and PHSL-CSE solid electrolytes. (e, f) Transmission electron microscopy (TEM) images of PHSL (Janus) composite nanofibers at different magnifications. (g, h) SEM images of PHSL (Janus) composite nanofibers at varying magnifications. (i) SEM image of a single Janus fiber (j) Corresponding elemental mapping of the Janus fiber, illustrating the spatial distribution of key elements and confirming the structural heterogeneity of the Janus architecture.

Fig. 3. Mechanical and thermal properties of composite solid electrolytes and their molecular coordination mechanisms. (a) TGA curves of PHS-CSE and PHSL-CSE composite solid electrolytes. (b) Stress-strain curves of PEO-LiTFSI, PHS-CSE, and PHSL-CSE composite solid electrolytes. (c) Raman spectra of PEO-LiTFSI, PHS-CSE, and PHSL-CSE composite solid electrolytes within the 730–755cm-1 range. (d–f) Schematic molecular coordination models of (d) PEO-LiTFSI, (e) PH-CSE, and (f) PHS-CSE electrolytes. (g) Mean square displacement (MSD) profiles of lithium ions in PEO-LiTFSI, PH-CSE, and PHS-CSE electrolytes. (h) Radial distribution functions (RDF) and coordination numbers (CN) for Li+and TFSI-1 in PEO-LiTFSI, PH-CSE, and PHS-CSE electrolytes. (i) RDF and CN for Li+ and thylene oxide (EO) segments in PEO-LiTFSI, PH-CSE, and PHS-CSE electrolytes. (j) Digital photographs of PEO-LiTFSI, PHS-CSE, and PHSL-CSE composite solid electrolytes before and after heating at 150°C for 30minutes. (k) Digital images showcasing the mechanical robustness of PHSL-CSE solid electrolyte films in various states, including original, curled, compressed, recovered, and in a suspended state under a 500g weight.

電化學性能方面,PHSL-CSE電解質在50°C時離子電導率達到7.60 × 10-4 S cm-1,鋰離子遷移數為0.75。Arrhenius圖顯示其活化能較低。拉曼光譜和密度泛函理論(DFT)計算表明,PVDF-HFP對TFSI-陰離子有較強吸附作用,促進鋰鹽解離并抑制陰離子遷移。分子動力學(MD)模擬也支持了鋰離子在復合電解質中更快的擴散。線性掃描伏安法(LSV)顯示電化學窗口寬達4.94 V。

Fig. 4.Electrochemical performance of composite solid electrolytes. (a) Electrochemical impedance spectroscopy (EIS) spectra of the PHSL-CSE composite solid electrolyte at various temperatures. (b) Arrhenius plots of ionic conductivity for PEO-LiTFSI, PHS-CSE, and PHSL-CSE composite solid electrolytes. (c) Chronoamperometric response of Li | PHSL-CSE | Li symmetric cell; inset: Nyquist impedance spectra recorded before and after polarization. (d) Linear sweep voltammetry (LSV) curves of PEO-LiTFSI, PHS-CSE, and PHSL-CSE composite solid electrolytes. (e) Energy level diagrams illustrating the highest occupied molecular orbital (HOMO) and lowest unoccupied molecular orbital (LUMO) for PVDF-HFP, PEO, LiTFSI, and succinonitrile (SN). (f) Binding energies of TFSI- with SN, PEO, and PVDF-HFP. (g) Critical current density (CCD) curves of PEO-LiTFSI, PHS-CSE, and PHSL-CSE composite solid electrolytes. (h) Interfacial resistance of the Li | PHSL-CSE | Li symmetric cell before and after 100 charge-discharge cycles. (i) Tafel plots of PEO-LiTFSI, PHS-CSE, and PHSL-CSE composite solid electrolytes.

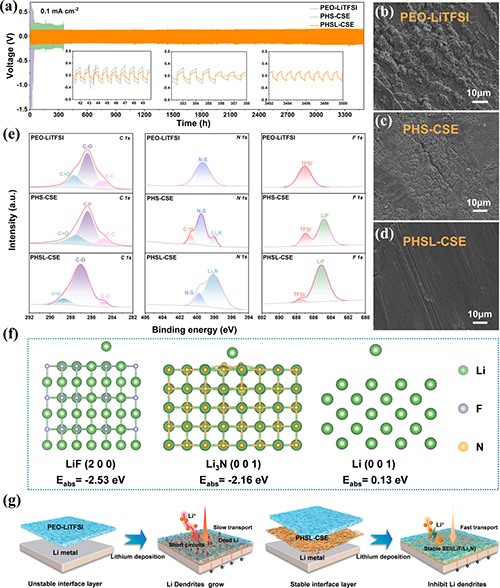

與鋰金屬負極的界面穩定性優異,Li/Li對稱電池循環穩定性超過3500小時,這得益于Janus結構促進形成了富含Li3N/LiF的穩定SEI層。XPS分析和DFT計算證實了SEI的成分及其對均勻鋰沉積和抑制枝晶生長的作用。XPS分析表明,循環后的Li | PHSL-CSE | Li電池在鋰負極表面形成了富含Li3N/LiF的SEI層。DFT計算(吸附能)證實,Li+優先吸附在LiF和Li3N界面,抑制了鋰枝晶的隨機形核和生長。這種穩定的SEI層有效隔離了電解質與鋰金屬的直接接觸,減少了副反應。

Fig. 5. Long-term cycling performance and morphological characterization of lithium metal surfaces.(a) Cycling stability of Li/Li symmetric cells with PEO-LiTFSI, PHS-CSE, and PHSL-CSE composite solid electrolytes at a current density of 0.1mAcm-2. (b-d) SEM images of lithium metal surfaces after 50 cycles for Li | PEO-LiTFSI | Li cells, and 100 cycles for Li | PHS-CSE | Li and Li | PHSL-CSE | Li cells. (e) XPS spectra of the lithium metal surfaces after cycling.(f) Adsorption energies of Li+ on LiF (200), Li3N (001), and Li (001) interfaces. (g) Schematic representation of the lithium deposition mechanism using PEO-LiTFSI and PHSL-CSE composite solid electrolytes.

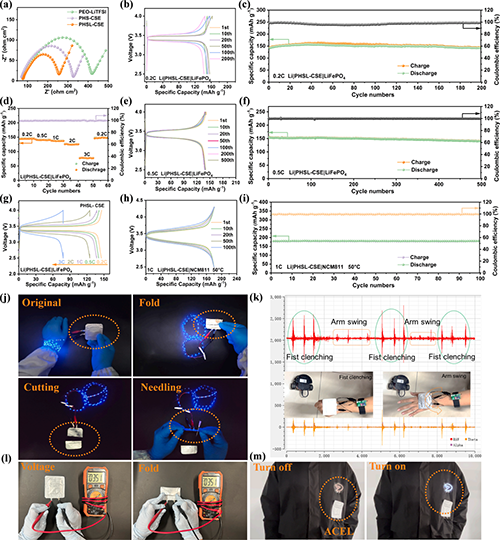

該電解質在全電池中也表現出色。LiFePO4 | PHSL-CSE | Li電池在0.5 C下循環500次后容量保持率仍很高。NCM811 | PHSL-CSE | Li電池在1 C下循環100次后也保持了良好的容量。更重要的是,采用PHSL-CSE電解質的柔性軟包電池展現出卓越的集成能力和機械魯棒性。即使在180°折疊、機械剪切、針刺和80°C熱暴露等極端條件下,軟包電池仍能穩定為ACEL發光器件和肌電傳感器供電,顯示出其在可穿戴電子設備領域的巨大潛力。

Fig. 6. Performance evaluation of all-solid-state lithium metal batteries at 50°C. (a) Electrochemical impedance spectroscopy (EIS) of Li | PEO-LiTFSI | LiFePO4, Li | PHS-CSE | LiFePO4, and Li | PHSL-CSE | LiFePO4 cells. (b) Voltage versus areal capacity curves for Li | PHSL-CSE | LiFePO4 cells. (c) Long-term cycling performance of Li | PHSL-CSE | LiFePO4 cells at a 0.2C rate. (d) Rate performance of Li | PHSL-CSE | LiFePO4 cells. (g) Voltage versus areal capacity curves at various rates for Li | PHSL-CSE | LiFePO4 cells. (e) Voltage versus areal capacity curves and (f) long-term cycling performance of Li | PHSL-CSE | LiFePO4 cells at a 0.5?C rate. (h) Voltage versus areal capacity curves and (i) long-term cycling performance of Li | PHSL-CSE | NCM811 cells at a 1C rate. (j) Optical images of Li | PHSL-CSE | LiFePO4 solid-state pouch lithium metal batteries, showing stable power output under various mechanical deformations including flat, bent, folded, cut, and punctured states.(k) A solid-state pouch cell integrated with an EMG armband, demonstrating the pouch battery''s capability to power a small vehicle via a flexible interface. (l) The pouch battery maintains stable output voltage even in a folded state. (m) Integration of the pouch battery with an ACEL flexible display, providing stable power to a flexible electronic device.

總而言之,這項研究通過Janus結構復合納米纖維膜的異質界面工程,成功開發了一種高性能、柔性的全固態電解質。該電解質集高離子導電率、高遷移數、優異的機械/熱穩定性和界面穩定性于一體,有效抑制了鋰枝晶生長,并在柔性電池應用中展現出巨大潛力。這項工作為開發用于儲能和可穿戴電子設備的高性能、柔性全固態鋰電池提供了新思路。

在此,感謝浙江省自然科學基金項目(LY21E030023)和浙江理工大學嵊州創新研究院基金項目(SYY2024C000008)的支持!

通訊作者簡介:胡毅,男,博士,教授,博士生導師。浙江理工大學紡織科學與工程學院(國際絲綢學院)副院長,主要從事非水介質染整新技術和柔性電子智能紡織品研究。以第一作者或通訊作者在 Advanced Functional Materials, Nano Letters, Energy Storage Materials, Nano Energy, Chemical Engineering Journal等刊物上發表SCI論文70余篇,授權和轉化國家發明專利30余項。獲得國家級教學成果二等獎和浙江省教學成果特等獎各1項;主持獲得中國紡織工業聯合會教學成果一、二、三等獎,浙江省自然科學獎三等獎和中國商業聯合會科技進步獎二等獎各1項。

原文鏈接:https://doi.org/10.1016/j.nanoen.2025.111136

- 天津科大劉葦教授、侯慶喜教授團隊 CEJ:高效多功能的Janus生物納米復合膜用于可控的高靈敏水下制動器 2023-10-27

- 南開曹墨源/北航劉克松《Adv. Sci.》:兼具Janus結構和光熱性能的智能除濕屋頂 2023-05-31

- 中科院蘇州納米所張珽研究員團隊 AM:具有Janus結構高機械強度的選擇性響應柔性力學傳感器 2023-05-31

- 吉林大學姜世梅教授團隊 JACS:基于超分子-共價協同策略構筑高性能單組分膠黏劑 2025-06-29

- 西華師范大學劉琦課題組 CEJ:無引發劑太陽能光聚合制備高性能、寬環境適應性和可回收水凝膠傳感器 2025-06-26

- 武漢紡大徐衛林教授、陳鳳翔教授/浣江實驗室王凱教授、孫書劍教授 Mater. Today 綜述:高性能纖維材料引領空天應用新時代 2025-06-25

- 北京大學龐全全教授團隊 Adv. Mater.: 氟化微疇調控-聚陽離子基固態聚合物電解質用于高電壓全固態鋰金屬電池 2025-03-14